Automotive Material UNIT-1 (2 Marks)

Unit -1

2 marks Questions.

1. What is Materials Science?

A. Materials science is a part of engineering that involves discovering and designing new materials and analysing their properties and structure. That information can then be used to make design choices. We can also use our knowledge to break materials apart and recombine them in creative ways. For example, did you know that nylon is created from oil? That kind of thing wouldn't be possible without materials science.

2. When will interstitial solid solution occur?

A. Interstitial solid solution is formed when atoms of small atomic radius fit into the empty spaces or interstices of the lattice structure of the solvent atoms as shown in Fig.

Since the empty spaces of the lattice structure are limited in size, only atoms with atomic radius less than 1 angstrom are likely to form interstitial solid solutions.

3. What is the difference between Schottky and Frenkel defect?

A.

Schottky Defect

|

Frenkel Defect

|

1. Equal number of cations and anions are missing from the lattice sites.

2. Found in highly ionic compounds with high coordination numbers and where the cations and anions are of similar size.

3. Density of the solid decreases

Examples: KBr, NaCl KCI

|

1. A cation leaves the normal lattice site and occupies an interstitial site.

2. Found in ionic compounds with low coordination numbers and where the anions are much larger in size than cations.

3. Density of the solid remains the same.

Examples:Zns, AgBr

|

4. What are the advantages of magnetic particle inspection?

A. Advantages of the Magnetic Particle method of Non-Destructive Examination are:

• It is quick and relatively uncomplicated

• It gives immediate indications of defects

It shows surface and near surface defects, and these are the most serious ones as they concentrate stresses

• The method can be adapted for site or workshop use

• It is inexpensive compared to radiography

• Large or small objects can be examined

• Elaborate pre-cleaning is not necessary

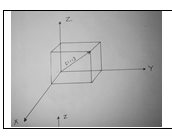

5. Draw the crystallographic directions for following Miller indices:

(i) [1 1 1] (ii) [1 0 1]

A.

6. Draw the crystallographic directions for following Miller indices:

(i) [1 0 0] (ii) [0 1 1]

7. Draw the cubic crystal planes for following Miller indices:

(i) (1 0 1) (ii) (1 1 1)

|

|

8. Draw the cubic crystal planes for following Miller indices:

(i) (0 0 1) (ii) (0 1 1)

(ii) Strain rate.

(iii) Temperature of metal and microstructure.

(iv) Hydrostatic pressure.

10. Differentiate between elasticity and plasticity.

11. Differentiate between ductility and malleability.

A.

Ductility

|

Malleability

|

Ductility is the ability of a solid material to undergo tensile stress. This property of a solid material can be measured and describes the extent to which the solid material can be plastically deformed without fracture. It is often depicted by the ability of the solid to stretch into a wire when pulled at the ends.

The mechanical property of ductility is quantified by the fracture strain, which is the strain at which the material fractures when increasing tensile stresses are applied along a single axis. The reduction of the area from the initial point to the fracture during the test can also be considered as a measure.

Ductility is a property specially looked for in metals. Metals have a very high ductility. Therefore, metals can be easily manipulated compared to other solid materials.

|

Malleability is the ability of solid materials to undergo compressive stress. Metals are highly malleable compared to non-metal materials. Therefore, metals can be shaped using forming methods such as forging, rolling, extrusion and indenting.

Since gold is highly malleable they can be forged into very thin foils, sometimes only few atoms thick.

|

12. Define the terms brittleness and hardness.

A.

Brittleness

|

Hardness

|

A material is brittle if, when subjected to stress, it breaks without significant deformation (strain). Brittle materials absorb relatively little energy prior to fracture, even those of high strength. Breaking is often accompanied by a snapping sound. Brittle materials include most ceramics and glasses (which do not deform plastically) and some polymers, such as PMMA and polystyrene.

Many steels become brittle at low temperatures (see ductile-brittle transition temperature), depending on their composition and processing.

|

Hardness is a measure of how resistant solid matter is to various kinds of permanent shape change when a compressive force is applied. Some materials (e.g. metals) are harder than others (e.g. plastics). Macroscopic hardness is generally characterize by strong intermolecular bonds, but the behaviour of solid materials under force is complex; therefore, there are different measurements of hardness: scratch hardness, indentation hardness, and rebound hardness.

Hardness is dependent on ductility, elastic stiffness, plasticity, strain, strength, toughness, viscoelasticity, and viscosity.

Common examples of hard matter are ceramics, concrete, certain metals, and super hard materials, which can be contrasted

|

13. What are the advantages of Liquid penetration test?

A.Advantages

High sensitivity ( small discontinuities can be detected )

Few material limitations ( metallic and non-metallic, magnetic and nonmagnetic, conductive and nonconductive materials may be inspected ). and Rapid inspection of large areas and volumes.

Suitable for parts with complex shapes.

Indications are produced directly on the surface of the part and constitute a visual representation of the flaw.

Portable (materials are available in aerosol spray cans) Low cost (materials and associated equipment are relatively inexpensive)

14. What are the advantages of Ultrasonic test?

A.Advantages

High penetrating power, which allows the detection of flaws deep in the part.

High sensitivity, permitting the detection of extremely small flaws.

In many cases only one surface needs to be accessible.

Greater accuracy than other non-destructive methods in determining the depth of internal flaws and the thickness of parts with parallel surfaces.

Some capability of estimating the size, orientation, shape and nature of defects.

Some capability of estimating the structure of alloys of components with different acoustic properties Non hazardous to operations or to nearby personnel and has no effect on equipment and materials in the vicinity.

Capable of portable or highly automated operation.

Results are immediate.

Hence on the spot decisions can be made.

15. What are interstitials in the crystals?

A. Interstitials are a variety of crystallographic defects where atoms assume a normally unoccupied site in the crystal structure. In interstitial defects two or more atoms may share one lattice site, thereby increasing its total energy. Alternative small atoms in some crystals may occupy interstitial sites in energetically favourable configurations, such as hydrogen in palladium. Interstitials can be produced by bombarding a crystal with elementary particles having energy above the displacement threshold for that crystal, but they may also exist in small concentrations in thermodynamic equilibrium

0 comments:

Post a Comment